Recycling big bags - why is it so problematic?

In Europe, around 120 million big bags, or flexible sacks, are placed on the market each year for transporting a variety of materials - from sand and grain to waste. Although these bags are indispensable in industry and agriculture, once they are used up they become an environmental challenge. This is why their recycling is a topic worth taking a closer look at.

What are big bags and where are they used?

Design and typical applications

A big bag, or FIBC (Flexible Intermediate Bulk Container), is a large flexible bag usually made of polypropylene (PP). Depending on the type, it can be coated or uncoated, and the most common variant has a load capacity of 1 tonne or a capacity of 1 cubic metre. There are, of course, models with both lower and higher capacities or volumes. It all depends on the intended use and the industry in which they are used. Although an empty bag weighs only a few kilos (2.5-3 kg on average), it is capable of safely carrying many tonnes of material.

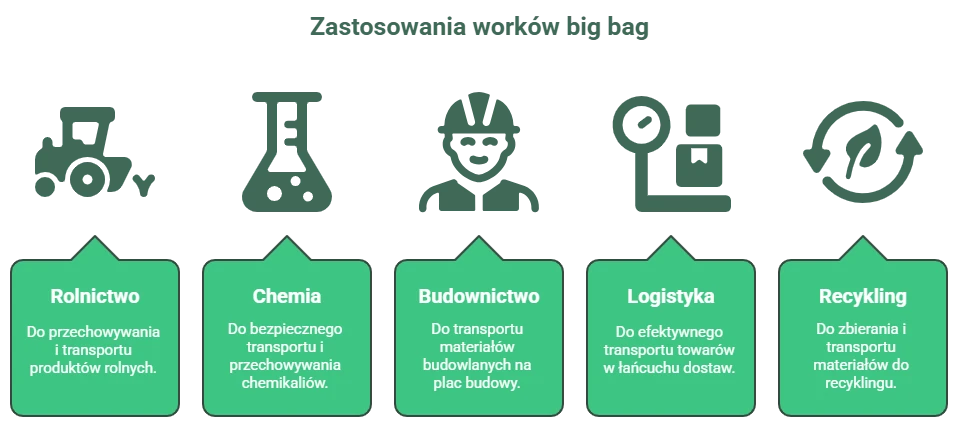

This type of packaging is often used in agriculture, chemicals, construction, logistics and also in the recycling industry. They are used for transporting and storing fertilisers, aggregates or foodstuffs (if they meet stringent requirements). They are also popular for transporting waste (scrap metal, dust, etc.).

The European FIBC market is a massive scale on a global scale - accounting for approximately 30% of the global FIBC market and growing at a rate of approximately 4.3% per year. According to Starlinger data, sales of 4-loop FIBC bags reaches up to 380 million each yearwhich means potentially up to 800,000 tonnes of raw material for recycling.

This is important because this specific figure - 380 million - comes from industry analyses and not just aggregate estimates. This allows us to talk about the real volumes and scale of the problem.

Need help managing your big bags? Write or call

Classification matters

From a recycling point of view, it is important to recognise which type of bag we are dealing with. Big bags vary, among other things, in terms of electrostatic protection - from type A (no protection) to type D (self-dispersing). Some contain so-called liners, i.e. inner liners made of other materials, often polyethylene (PE).

Depending on their use, used big bags can be classified under different waste codes. The most commonly mentioned are:

- 15 01 02 - plastic packaging (clean),

- 15 01 10* - packaging contaminated with hazardous substances.

Why is big bag recycling a challenge?

Recycling of big bags - although possible in theory - faces a number of serious barriers in practice. Although the bags themselves are mainly made of polypropylene (PP), a material well known to the recycling industry, their structure and conditions of use mean that the recovery of the material is not always straightforward or cost-effective.

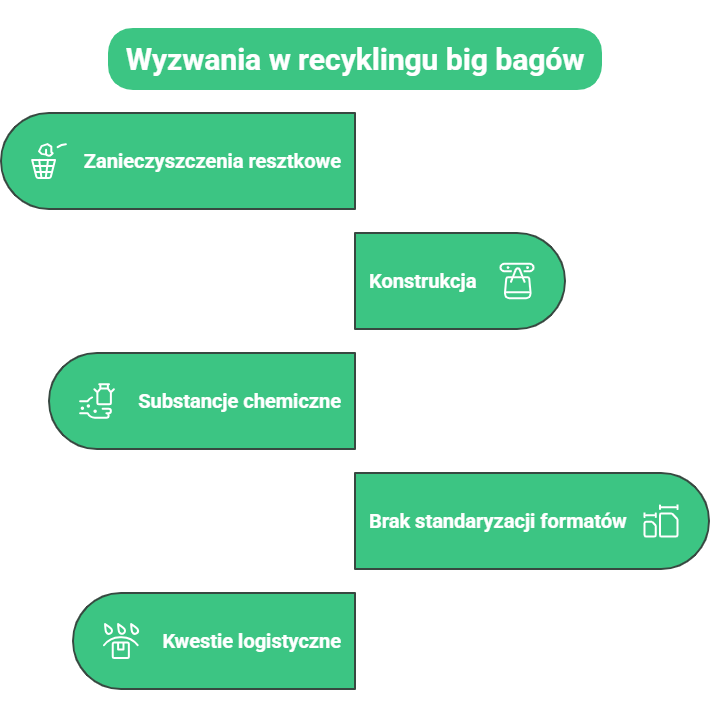

First, cleanliness

One of the most difficult problems is residual contamination. Big bags often transport fertilisers, industrial dusts, chemical raw materials and even food materials. Even after emptying, many of these remain inside the bag, sticking to the walls or penetrating the fabric structure. This requires time-consuming and expensive cleaning, which does not always produce satisfactory results. If this step is missed - or carried out inaccurately - the processed material will be of poor quality and unsuitable for further production.

The problem lies in the construction

Another difficulty is the construction of the bags themselves. Although the main raw material is polypropylene, many models use additional components - liners (protective inserts), sewing threads, handles, labels or coating layers. These additives, which are made of different plastics (e.g. PE, PA, EVOH), are difficult to separate. As a result, a product arrives at the recycling plant that is not materially homogeneous, which significantly limits the processing options and affects the final quality of the regranulate.

When chemistry gets in the way

No less of a challenge are the chemicals contained in the material itself. Many big bags, especially types C and D, contain antistatic additives, conductive fibres or specialised pigments. Particularly problematic are dyes in black, which absorb light and thus prevent effective sorting using popular NIR (near infrared analysis) technologies. Such materials often end up as unsortable fractions, even though they could in theory be recovered.

From want of ...

Technological problems are also compounded by the lack of standardisation of formats. Big bags differ not only in size, but also in construction, load capacity and sewing method. This diversity makes it almost impossible to create a one-size-fits-all recycling line. Instead of an automated process, individual approaches and manual selection are needed, which increases costs and reduces the efficiency of the entire process.

Logistics of the problem

A final, but equally important, obstacle is logistical. Big bags - despite their large capacity - are very light. This means that they take up a lot of space in transport, but deliver little raw material by weight. For a recycler, this is unprofitable, especially when sourcing sources are dispersed and volumes from one location are small. In addition, improper storage - e.g. in high humidity conditions or with UV exposure - leads to fibre degradation. This, in extreme cases, can make big bag recycling impossible. The material becomes brittle, cracks and loses its mechanical properties.

Putting all these barriers together, it is easy to understand why, despite technological advances and increased awareness, big bag recycling is still not reaching a satisfactory level. However, this does not mean that it is impossible. On the contrary, a growing number of initiatives show that, with the right approach and the cooperation of the various links in the value chain, this potential can be effectively realised.

What to do with used big bags? Practical solutions

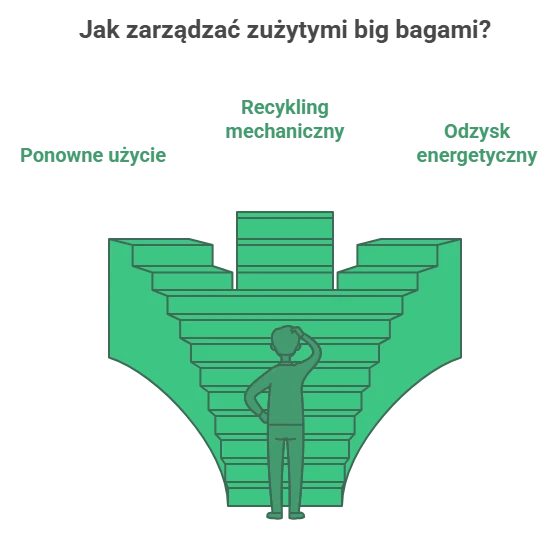

Used big bags can be managed in several ways - the choice depends on their condition and previous use. The best option, if the quality of the material allows it, is reuse. This requires compliance with safety standards, thorough cleaning and a technical inspection. There are professional bag reconditioning companies in Europe. They can extend their life cycle by up to five times, reducing CO₂ emissions and logistical costs.

If the bags do not qualify for re-use, mechanical recycling is possible. The process involves the removal of accessories (liners, threads, labels), thorough washing and shredding of the material. The clean granulate can be used to produce new bags or other PP products. In the ideal model, the entire process takes place in a closed loop - from waste to new big bag.

In cases where the bags are too contaminated or of unknown origin, energy recovery remains. This is the least desirable option, but sometimes necessary. Especially in cases where the bag contains difficult-to-remove liners or toxic residues.

Whatever the path, how the bags are prepared is crucial. Storing them under a roof, away from moisture and UV rays, separating the liners, sorting them by content type and documenting the batch - all measures that realistically increase the chances of recycling and reduce material loss.

Where others see a problem, we see potential. Call or write and find out how we can help you

Legislation and legal developments

The most important act currently shaping the future of big bag recycling is the PPWR regulation (Packaging and Packaging Waste Regulation), which was adopted in February 2025. Unlike previous directives, the PPWR applies directly in all Member States, so that its provisions will be applied uniformly. The main aim of the regulation is to reduce packaging waste and increase the proportion of materials in a closed loop. By 2030, all packaging is to be designed to be recyclable and plastic packaging must contain a minimum of 30% of recycled material.

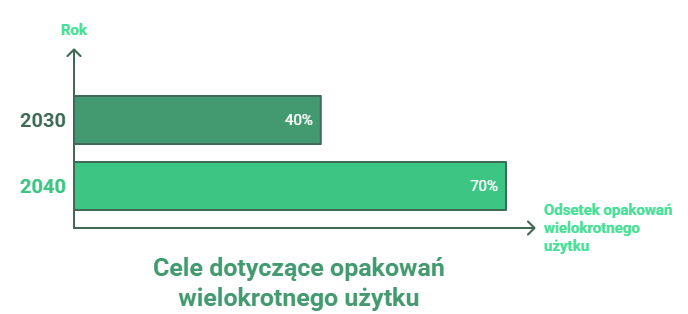

Reuse targets are also an important element of the new legislation. From 2030, at least 40% of transport packaging, including big bags, is to function in reusable systems. This will increase to 70% by 2040. This implies the need to develop pooling systems (promoting the use of the packaging by multiple operators instead of introducing new bags to the market each year). It will also be important to better design them for durability and to provide reconditioning procedures. At the same time, the allowable proportion of void space in pooling and transport packaging has been reduced to a maximum of 50% to reduce inefficient transport and emissions.

For big bag manufacturers and users, the new regulations represent both a challenge and an opportunity. On the one hand, they mean additional obligations and the need to adapt the design of the bags to the rules of the Design for Recycling. On the other hand, however, they can accelerate the development of recycling technologies and improve the efficiency of the overall waste management system. The example of France, where A.D.I.VALOR system achieves more than 90% efficiency in the collection of agricultural bags, shows that high levels of recovery are possible. In Poland, the implementation of the PPWR may provide the impetus to create similar solutions and make real use of the potential of big bags in a closed loop economy.

Recycling is not the end

The recycling of big bags is a process that requires the involvement of many parties - producers, recyclers as well as the users themselves. Although technological and logistical barriers make the recovery of this packaging not straightforward, solutions already exist and are showing their effectiveness in many countries. The key, however, is a responsible approach that starts at the user stage. It is the responsibility of the user to properly prepare and manage the waste.

In practice, this is not always the case: due to a lack of knowledge or insufficient information, companies make mistakes that result in the bag not being recycled, but ending up in an incinerator or landfill. However, many of these problems can be avoided if you cooperate with the an experienced company to advise on bag preparationwhere to hand them in and how to comply with all the formal requirements. Professional support means not only greater confidence in compliance, but also real savings in time and money.

If, on the other hand, you are confident that you can manage on your own but are having difficulty finding a reliable haulier to deliver your waste to a suitable installation, it is worth using the tools available. One of them is the database on odpadytransport.co.ukwhere you will find hundreds of transport companies specialising in waste transport. It's a simple solution that allows you to find a partner quickly, while at the same time giving you the confidence that your waste will go where it will actually be treated properly.