Collection of biowaste for recycling - comprehensive and trouble-free

In light of the European requirements for a circular economy, biowaste has gained strategic importance. Their effective management not only relieves landfills, but recovers natural resources, reduces greenhouse gas emissions and promotes raw material independence. In this article, we take a closer look at the scale of bio-waste production in Poland, the main sources of bio-waste, the challenges of industrial management and the opportunities for re-use.

Need help organising your bio-waste collection?

According to the CSO report, entitled Housing and community infrastructure in 2021. the amount of bio-waste produced by a statistical Pole increased from 4.7 kg in 2010 to 48.5 kg in 2021. In 2021 alone, more than 13 million tonnes of municipal waste were generated in Poland, of which almost 2 million tonnes were bio-waste.

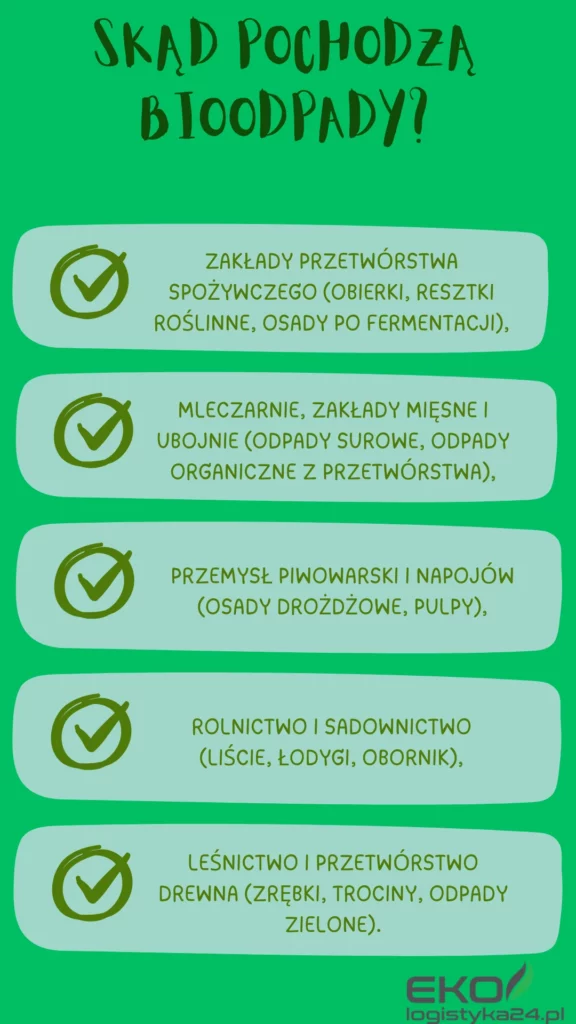

Main sources of biowaste in industry

Most bio-waste comes from:

- Food processing plants (peelings, vegetable residues, fermentation sludge),

- Dairies, meat factories and slaughterhouses (raw waste, organic waste from processing),

- Brewing and beverage industry (lees, pulps),

- Agriculture and horticulture (leaves, stems, manure),

- Forestry and wood processing (wood chips, sawdust, green waste).

How is bio-waste used?

Bio-waste is used in a number of ways and its further processing depends on the type of waste and the objective to be achieved. Below, we describe the most common uses for this fraction.

Transformation into compost

In composting plants, bio-waste decomposes under the influence of oxygen, bacteria and high temperatures. This process results in compost - a valuable fertiliser used in agriculture, horticulture and the reclamation of degraded land.

If you run a processing plant or a farm, you not only gain a means of disposal, but also a viable product for further use.

Biogas and energy production

Anaerobic digestion plants (biogas plants) convert bio-waste into biogas - a mixture of methane and carbon dioxide. This can be used to produce electricity, heat or as a fuel. Digestate - the residue from the process - is also obtained from the fermentation process and can be used as organic fertiliser.

This solution is ideal for large volumes of bio-waste from the food industry, vegetable processing plants, dairies or catering.

Recovery of organic fractions for further processing

In modern installations, valuable fractions such as cellulose fibres, sugars or technical fats are recovered from biowaste. This type of processing is mainly developing in the closed-loop economy sector.

If you work with partners that process bio-waste in an advanced way, you can realistically participate in eco-processes and reduce your carbon footprint.

What is worth knowing?

By managing your bio-waste you reduce the amount of waste going to landfill, which is not only environmentally friendly but also in line with current legislation (EU and national). In some cases, the management of bio-waste is even an obligation - e.g. for large food businesses or local authorities.

Challenges in bio-waste management

Lack of uniform segregation standards

For the producer of biowaste the biggest problem is the ambiguity of the rules and local interpretations. Depending on the province or the operator of the installation, the same waste may be classified as bio-waste or as mixed waste.

This raises risks:

- misclassification of waste in BDO records,

- refusal of the recycling facility to accept the waste,

- fines or penalties for incorrect waste transfer,

- the need for additional consultations with the recipient, which lengthens procedures.

For large plants, this means the need to employ a waste management specialist or outsource environmental services - increasing operating costs.

Contamination of the bio fraction

If your company produces large quantities of biowaste, for example from food processing, catering or retail, you know very well how difficult it is to keep the bio fraction clean. Bulk packaging, labels, foils, metal machine parts and even employee gloves can accidentally end up in the bio-waste container.

Consequences include:

- additional costs for internal segregation,

- higher collection rates (installations add a charge for cleaning),

- discarding entire batches of biowaste and having to reclassify it as mixed or even hazardous waste,

- loss of the opportunity to take waste to a composting plant (e.g. due to its plastic content).

From the producer's point of view, any such situation is a waste of time and money - especially if the waste has to be transported to another, more expensive plant.

Inadequate infrastructure

Companies that produce biowaste regularly and in large quantities very often face a lack of recipients or facilities that can accept it continuously and safely.

The most common problems are:

- lack of treatment facilities for a particular type of bio-waste (e.g. animal raw material waste, out-of-date packaged food),

- insufficient plant capacity in the region - you have to wait for collection or transport the waste hundreds of kilometres away,

- unclear conditions for accepting waste - some plants require a declaration of composition, chemical analysis or veterinary documentation.

As a result, biowaste producers are forced to:

- entering into short-term, uncertain contracts with customers, which destabilises the production and logistics process.

- storing waste for longer periods of time, which creates the risk of odour, fermentation and inspection by the Sanitary Inspectorate or the Inspectorate of Environmental Protection,

- looking for expensive, emergency solutions such as disposal to an incinerator or to a neighbouring country.

Opportunities and recommendations

- The expansion of the biogas network can contribute to the local management of bio-waste and the production of renewable energy,

- Standardisation of container labelling and educational campaigns will improve the quality of selection,

- Support for companies that process biowaste can develop the market for secondary raw materials,

- Better sector statistics will help identify the most wasteful industries.

Recycle bio-waste with our help

Bio-waste is becoming an increasingly important part of Poland's and Europe's environmental transformation. Both local governments and companies need to adapt their practices to the challenges of their recovery. With the increasing mass of bio-waste and its importance as a raw material, infrastructure development and better education of the public should be a priority in the coming years.

Want to find out more about legally donating your biowaste or need support with managing it? Contact the experts at Ecology24 - We will assist you throughout the process.

Do you have questions about bio-waste management?

Check out our FAQ section below - we have collected the most common concerns and specific answers there.

If you do not find the information you need there, Write to us or call us - we will be happy to help.

Definitions

Bio-waste is biodegradable waste made from raw materials of plant or animal origin - e.g. food scraps, grass cuttings, manure, food processing waste.

Industrial bio-waste includes.

From food processing:

- Fruit and vegetable residues (peelings, sorting waste, leaves, roots, pulp residues)

- Waste from juice, concentrate, compote production (stones, peel, pomace)

From the baking and milling industry

- Chaff, sieves, waste flour, acidified products

Dairy waste

- Whey, out-of-date yoghurt and milk, filtration residues

Waste from feed and fodder production:

- Not meeting quality standards, not containing drugs

Green waste from industrial site maintenance

- Grass, branches, leaves from landscaping companies

If any of the above waste contains chemical additives, non-biodegradable substances, packaging, residues of veterinary medicines, preservatives, it may not qualify as bio-waste.

Green waste is a subcategory of bio-waste that includes only purely plant fractions - e.g. leaves, branches, grass. Bio-waste can also include food scraps.

Recycling and management of biowaste

Most often by composting (aerobic process) or anaerobic digestion (biogas and fertiliser production). Some bio-waste can also go to incineration plants with energy recovery.

Yes - in terms of the regulations, both composting and methane digestion are considered forms of organic recycling.

The waste goes to composting facilities or biogas plants, where it is transformed into compost, biogas, heat, electricity or digestate - a product with fertilising properties.

Yes - but provided it does not contain hazardous substances and has been properly separated (e.g. food separated from packaging). Otherwise it may be considered mixed waste.

Transport

Yes. The transporter of bio-waste must have a waste transport permit through registration in the BDO register under section VII. In addition, the waste must be classified according to the waste catalogue.

In Poland, this will be a KPO (Waste Transfer Note) in the BDO system, but in the case of cross-border shipments - Annex VII (for intra-EU shipments) or a notification and consent (if bio-waste is classified as other than Green List).

Yes, but on condition that the provisions of Regulation (EC) 1013/2006 are met and that they are treated in the country of collection in an environmentally sound manner. In practice, the export of bio-waste is rare and mainly limited to cooperation with specialised installations.

Documentation

Yes - the obligation applies to any entity that generates non-municipal waste (e.g. restaurants, processors, wholesalers, farms over 75 ha) and transfers it to a collector.

Yes - current records (KPO and KEO) must be kept in the BDO system, including type of waste, mass, date of transfer and recipient details.