Recycling rubber waste - how to turn a problem into a resource for the future?

What does rubber waste recycling look like in practice and why is it a topic that should be of interest to every producer and holder of industrial waste? With dynamic changes in legislation and rising raw material costs, recycling is becoming not an option, but a necessity. In this article, we explain the most common ways to recycle rubber waste. We also point out what challenges recyclers face.

Need help organising your rubber waste collection?

Scale of the problem - rubber waste in Europe and Poland

In an era of increasing environmental awareness, the topic of rubber waste recycling is gaining importance. Although there are no specific figures to indicate the exact amount of such materials produced in Europe, it is known that more than 3.5 million tonnes are used tyres.

According to report from the European Tyre & Rubber Manufacturers' Association of 2019, the largest producers of waste tyres are:

COUNTRY | TOTAL AMOUNT OF WASTE TYRES PRODUCED | MATERIALLY RECYCLED TYRES | ENERGY-RECYCLED TYRES |

|---|---|---|---|

GERMANY | 434 000 tonnes | 295 000 tonnes | 137 250 tonnes |

FRANCE | 422 579 tonnes | 222 357 tonnes | 223 054 tonnes |

ITALY | 384 000 tonnes | 170 842 tonnes | 170 000 tonnes |

POLAND | 268 500 tonnes | 127 000 tonnes | 84 000 tonnes |

SPAIN | 238 080 tonnes | 158 327 tonnes | 79 753 tonnes |

Although the scale of the problem is huge, there are still many countries that do not have sufficient technology to effectively manage this waste. This is a challenge, but also a huge opportunity for the circular economy.

Rubber is not plastic - classification misunderstandings

Many people - including businesses - mistakenly regard rubber waste as plastic. Why?

- Visual and functional similarity - many rubber products resemble flexible plastics.

- Synthetic origin - most rubbers are made from polymers similar to plastics.

- Unclear classification - even within the waste industry there is no uniform approach.

However, the key differences cannot be overstated:

FEATURE | PLASTICS | GUMA |

|---|---|---|

STRUCTURE | Thermoplastic | Cross-linked (vulcanised) |

PROCESSABILITY | Easy (melting) | Difficult (pyrolysis/devulcanisation necessary) |

ELASTICITY | Limited | Very high |

RECYCLING | Mechanically possible | Complex, costly, often chemical |

This distinction affects not only the recovery technology, but also the classification of the waste, the choice of catalogue code and the record-keeping obligations.

Types of rubber waste - more than just tyres

When we think of rubber waste, our most common association is used tyres. However, it is worth taking a closer look at these materials because, contrary to appearances, it is a somewhat more complex issue. We can distinguish between different types according to the following categories:

Origins:

- tyres (end - of - life tyres) - passenger cars, trucks, industrial, agriculture

- technical components - gaskets, mats, belts

- consumer products - gloves, footwear, exercise mats

- production waste - offcuts, vulcanisation waste

The industry in which they arise:

- motorisation,

- construction,

- agriculture,

- heavy industry,

- sport,

- medicine

Chemical composition:

- SBR (styrene-butadiene rubber) - is the most common type of synthetic rubber, used primarily in tyre production. It is characterised by very good abrasion resistance and good elasticity, making it ideal for high friction conditions. Although cheap and durable, it has one major drawback - it tolerates contact with oils and fuels poorly and is therefore not suitable for all industrial applications.

- NR (natural rubber) is a plant-based rubber derived from rubber tree latex. It has excellent elasticity, high tensile strength and excellent low-temperature properties. However, it handles oils, chemicals and ozone poorly.

- EPDM (ethylene propylene diene monomer) - is resistant to ozone, UV rays, water vapour and atmospheric conditions. Ideal for window seals, roofs, cooling systems. Not suitable for contact with oils and fuels.

- NBR (nitrile butadiene rubber) - its main advantage is its very good resistance to oils, greases, fuels and fats. Used in the automotive and hydraulic industries - e.g. for hoses, seals and protective gloves.

- CR (chloroprene rubber - neoprene) - is a rubber with balanced properties: flexible, resistant to ageing, chemicals and also slightly flame-resistant. It is used in protective clothing, belts and seals.

- IIR (butyl rubber) - this type of rubber is known for its very low gas permeability, which is why it is used, for example, in inner tubes and vacuum seals. It insulates well, but is less resistant to oils.

This diversity makes recycling difficult, but at the same time opens up opportunities for alternative uses.

Recycling rubber waste - how to recover valuable raw materials?

Due to its composition and limited technological options, recycling of rubber waste most often takes two forms:

Mechanical recycling

- Grinding and granulation of waste - one of the simplest and most commonly used waste treatment methods. It involves used rubber products - usually tyres - being first mechanically shredded into smaller pieces and then ground into granules or rubber dust. The process first separates out the steel and textiles that are additives in the tyres. What remains is the pure rubber fraction, which can be used to make sports mats, playground surfaces, rubber asphalts or noise pads. This method has many advantages - it is technically simple, relatively cheap and does not require complex installations. Its disadvantage, however, is that it does not restore the rubber's original properties, such as elasticity - so such granules can only be used for less demanding applications and not for new tyres or seals.

Chemical recycling

- Pyrolysis - a process in which organic materials, such as used tyres or plastics, decompose when exposed to high temperatures, but without oxygen. As a result, there is no combustion, but a slow breakdown of the chemical structure of the material. Pyrolysis turns waste into three main products: pyrolysis oil, which can be used as a fuel; gas, which is often used to power the process itself; and solid residual material, usually in the form of carbon black or carbon. The biggest advantage of pyrolysis is that it allows valuable raw materials to be recovered from waste that is difficult to dispose of, such as tyres. Unlike incineration, the process offers the chance to reuse the recovered components rather than destroying them irrevocably. This makes pyrolysis increasingly seen as an important part of a circular economy.

- Devulcanisation - recovers used rubber, such as that from tyres, and restores its ability to be further processed. Rubber in industrial products is usually vulcanised - that is, its molecules are permanently bonded together by sulphur, making it durable and flexible, but also difficult to recycle. In devulcanisation, these sulphur bonds are partially broken, making the material more malleable and amenable to re-forming. The rubber recovered in this way, called regenerate, can be used, for example, to make mats, gaskets or as an additive for new rubber compounds. This is one of the more promising methods for recovering rubber, although technically more difficult and less widespread than pyrolysis.

Other ways

When recycling of rubber waste by the above two means fails, a third option remains:

- Co-combustion in cement plants - this process results in waste being burned together with a traditional fuel, such as coal, in cement kilns. Such a kiln reaches very high temperatures (even above 1,400°C), so that the waste burns completely and the energy released is used to produce cement. Used tyres are particularly valued as an alternative fuel because they have a high calorific value, comparable to coal. In addition, the coal and steel they contain can partially replace the raw materials used to produce cement clinker. The advantage of co-incineration is that the waste does not go to landfill, while at the same time reducing the consumption of fossil raw materials. The downside, on the other hand, is that unlike material or chemical recycling, rubber material is not recovered, but irretrievably incinerated - so it does not fit into the model of a closed-loop economy.

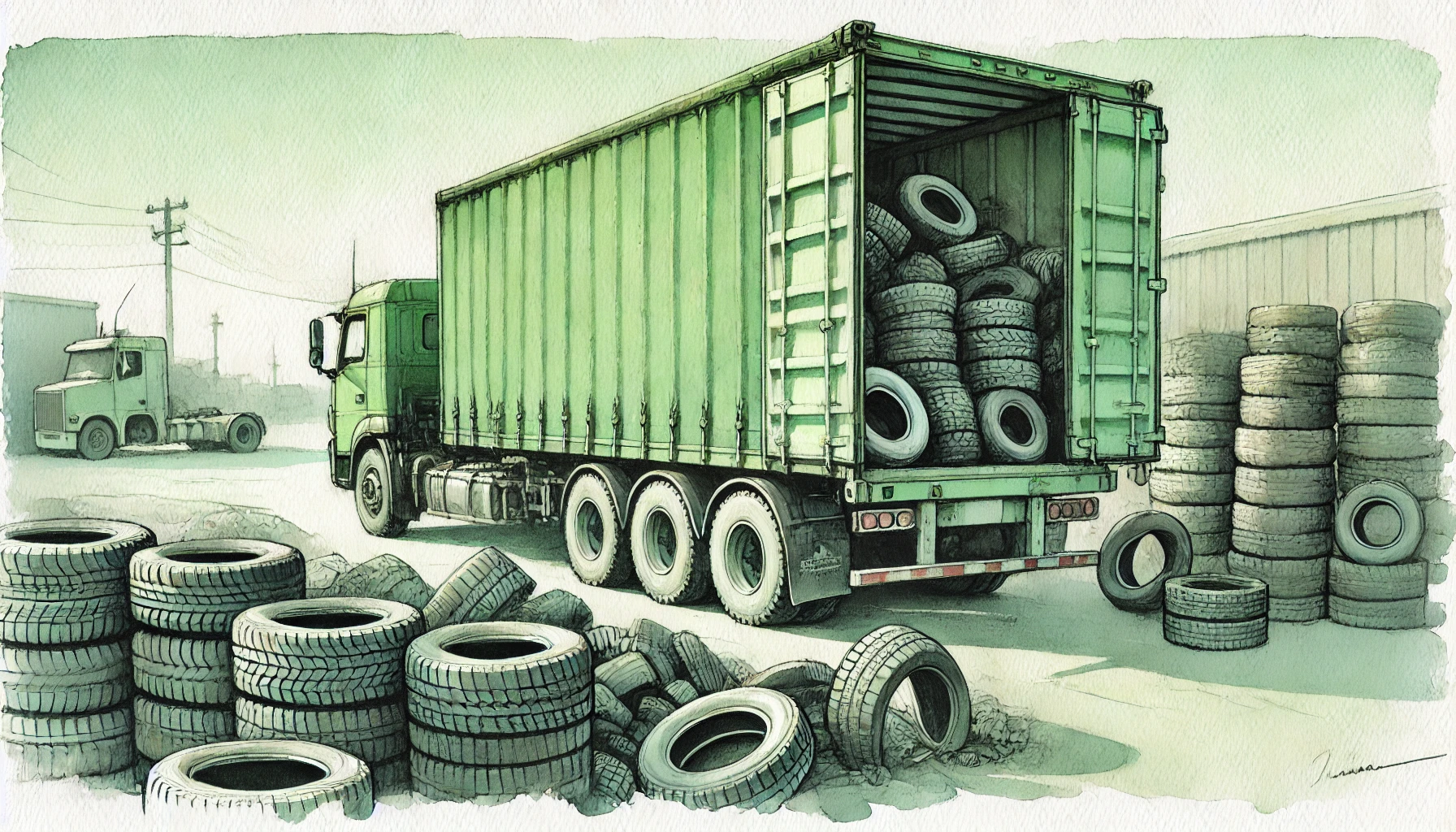

Transport of rubber waste - regulations, risks and requirements

The transport of waste tyres and other rubber waste is a challenging task due to both the characteristics of the material itself and the complex legal requirements. One of the main logistical problems is the large volume of such waste. Tyres, although relatively light, take up a lot of space, which translates into high storage and transport costs. This often requires special methods for compressing or cutting them to optimise loading space.

Another aspect is international regulation. The shipment of rubber waste between and beyond the member states of the European Union is subject to the provisions of Regulation (EC) No 1013/2006. This implies the need for the relevant notification, authorisation and documentation procedures, which significantly lengthens and complicates the whole process.

Illegal export of tyres, which are sometimes wrongly or deliberately classified as 'used' rather than waste, is also a significant risk. This practice is intended to circumvent notification requirements and environmental charges, but has serious legal consequences.

Finally, depending on the international relationship and the country of origin and destination of the cargo, additional systems and registers may apply, such as BDO in Poland, SENT for domestic shipments with supervision, or the notification notification obligation for international transport. All of these elements mean that the transport of rubber waste requires careful planning, knowledge of regulations and cooperation with experienced partners.

Recycling rubber waste - see how we can help you

As an experienced waste management partner, Ecologistics24 offers:

- Selection of legitimate carriers with full authorisations

- Organising national and international transport

- Support in BDO, SENT, notifications

- Contact with reliable recyclers in Poland and Europe

- Optimisation of recovery and logistics costs

With us, rubber waste gets a second life. Get in touch and see how we can help you.