Pallet recycling step by step - what is worth knowing?

Different types of pallets are used on the market. Of the almost 500 million that enter the European market each year, not all are reusable. What can be done with such pallets legally and without harming the environment? Here is a comprehensive guide to their management and recycling options.

Introduction to the subject of pallets

What exactly are pallets and what are they used for?

A transport pallet is a standard load carrier that allows goods to be moved easily with forklifts or other storage equipment. They are indispensable in logistics, storage and transport.

In which industry are pallets most popular?

Pallets are widely used in many industries:

- transport and logistics

- food (for FMCG - Fast Moving Consumer Goods)

- industrial, construction, chemical

- commercial and e-commerce

Don't know what to do with used pallets lying around in your warehouse? Write to us or call us

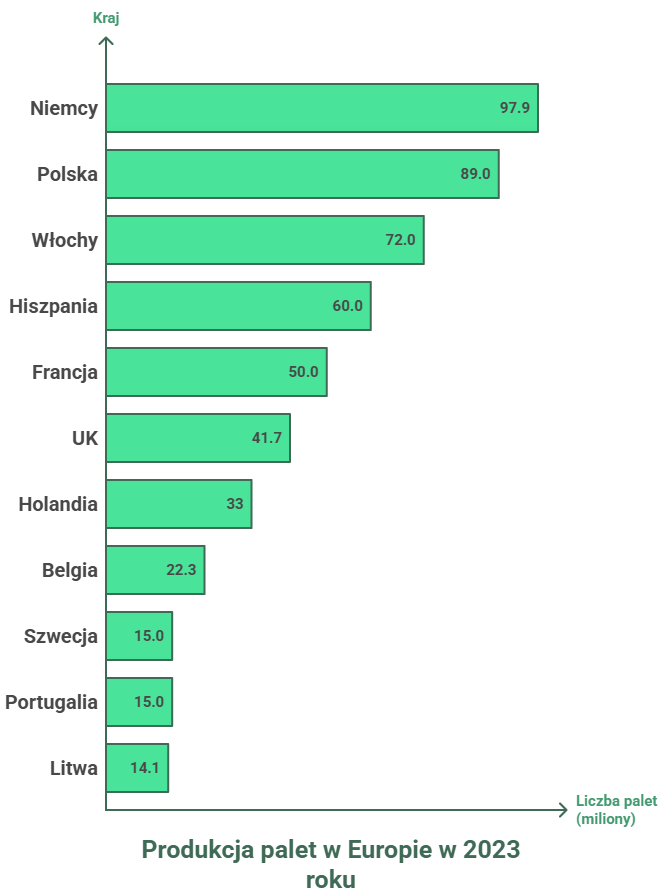

Largest pallet producers - overview of countries

According to the FEFPEB report (European Federation of Pallet and Wood Packaging Manufacturers) in 2023, approximately 495 million pallets will be produced in Europe. The following countries had the largest share of the pallet market:

| Country | Number of pallets (million) |

|---|---|

| Germany | 97,9 |

| Poland | 89,0 |

| Italy | 72,0 |

| Spain | 60.0* (approximate value) |

| France | 50,0 |

| Netherlands | 33,0 |

| Belgium | 22,3 |

| Lithuania | 14,1 |

| Portugal | 15,0 |

| Sweden | 15,0 |

| UK/Ireland | 41,7 |

| Total | 495,0 |

How many pallets in a year end up as waste?

Although there are many types of pallets in circulation, most data on their life cycle is only available for the most popular ones, i.e. wooden pallets. According to statistics, there are more than 4 billion wooden pallets in circulation in Europe. In addition, more than half a million new pieces are added to this pool every year.

It is assumed that the average the shelf life of a wooden pallet is around 5-7 years, depending on the industry and degree of exploitation. This, in turn, means that each year roughly 14-20% of this resource can be considered as used (i.e. potentially energy recoverable or recyclable). That is, on average, 560 - 800 million pallets go out of circulation every year.

Under which codes are pallets most commonly classified?

It all depends on the material from which they are made. They are most commonly differentiated as:

| WASTE CODE | DESCRIPTION |

|---|---|

| 15 01 01 | Paper and cardboard packaging |

| 15 01 02 | Plastic packaging |

| 15 01 03 | Wood packaging |

| 15 01 04 | Metal packaging |

Due to the presence of contaminants, they may also be classified under the following waste codes:

| WASTE CODE | DESCRIPTION |

|---|---|

| 15 01 10* | Packaging containing or contaminated with residues of hazardous substances |

| 15 01 11* | Metal packaging containing hazardous porous structural reinforcement elements (e.g. asbestos), including empty pressure containers |

If the pallets or crates were only used to transport neutral building materials (e.g. bricks, tiles, cement in sealed bags, plasterboard), they do not qualify as 15 01 11*.

However, if it was permanently contaminated with hazardous substances:

- Residues of paints, solvents, epoxy resins, adhesives with isocyanates,

- packaging of construction chemicals (impregnants, fungicides, polyurethane adhesives)

then code 15 01 11* is indeed appropriate.

How to prevent pallet waste?

Pooling

By sharing pallets in systems such as EPAL (open pool) and CHEP/LPR/IPP/PRS (closed pool), the life of the pallets can be extended.

BENEFITS - reduced costs, standardisation, environmental friendliness

FAILURES - limited control, need for reverse logistics

Rental and reuse

Companies are increasingly renting pallets or using already used units.

BENEFITS - lower purchase costs, flexibility

FAILURES - technical condition may require inspection

Repair

Very often traders also choose to repair their pallets. In Poland, repairs account for only 5.3% compared to production, while in the UK it is as much as 56.5%.

BENEFITS - longer life cycle, lower costs

FAILURES - need for appropriate tools and knowledge

What do you do when pooling does not work, pallet rental is not an option and pallet repair is not worthwhile? Write or call, we will find a solution

Why is it challenging to recycle pallets and more?

Pallets vary in construction (they contain many different components) and use (depending on the industry and the goods being transported), making them difficult to process.

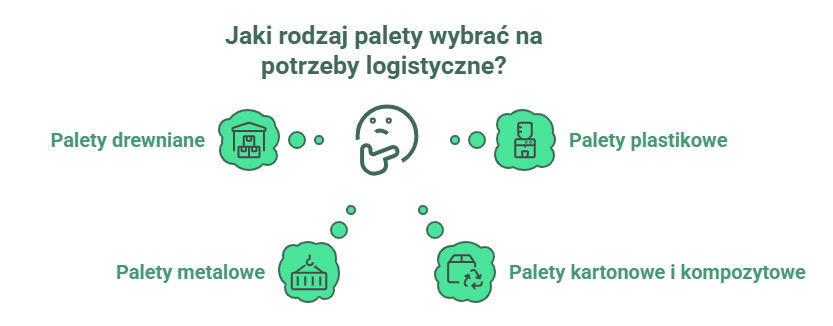

Wooden

- Strengthswidely available, relatively easy to repair

- Problems: nails, staples and other metal elements hinder recovery; some pallets also contain paint, impregnation or protective agents; moisture promotes mould growth and reduces the value of the material.

- Recycling: the recovery hierarchy involves sorting and repairing first, then processing into material for reuse (e.g. plates), and lastly incineration with energy recovery.

Pterrazzo

- Strengths: durable, resistant to moisture and easy to clean; in some sectors (food, pharmaceuticals) essential for hygiene reasons.

- Problems: the variety of plastics (mostly PP and HDPE) makes it difficult to recycle pallets; contamination with oils or chemicals can preclude recovery; cracks limit reuse.

- Recycling: mostly mechanical (shredding, regranulate), sometimes with producer buy-back programmes; effective if the batch is homogeneous and clean.

Metal

- Strengths: high strength, long service life; steel and aluminium have a high scrap value and can be fully reproduced in the metallurgical process.

- Problems: pallet weight and higher initial cost; contamination problems (e.g. rubber caps, corrosion); if the pallet has been in contact with chemicals, it may be classified as hazardous waste (code 15 01 10*).

- Recycling: relatively simple - scrapping and remeltingbut only if the material is not contaminated.

Cardboard/cardboard

- Strengths: lightweight, fully recyclable in recycled paper; biodegradable; attractive as a single-use solution for light loads.

- Problems: low resistance to moisture and mechanical damage; contaminated with oil or grease unsuitable for traditional paper recycling; low durability limits the possibility of reuse.

- Recycling: in their pure form, they may end up in the waste paper stream; in practice, they often end up in incinerators as an alternative fuel, as they are difficult to recover on a large scale.

The most common mistakes in pallet management

- Mixing of different materials and fractions - increases costs

- Lack of quality selection - hinders pallet repair and recycling

- Outdoor storage - pallets deteriorate when exposed to sunlight and moisture

- Stretch wrapping too tight - makes inspection difficult

- Lack of batch documentation - difficulty in assessing further use

- Violations of pooling rules - may result in legal consequences

Pallet recycling pays off if you know how to do it

Increasingly, pallets are being manufactured from recycled materials. The key is the quality of the recycled raw material, which must ensure durability, safety and repeated use. Innovations in recycling and materials science support this trend.

Managing used pallets can be easy - if a company chooses to work with professionals. Ecologistics24 has been operating on the market for more than a decade. So far, we have only assisted on the technical side by mediating waste transport permits. However, in order to meet customer expectations, we have expanded our portfolio of services to include waste management, including waste from pallets.

The positive reception of the new service has led us to develop it gradually, adapting it to the trends of the waste industry while making sure that customers receive reliable and timely assistance, in line with legislation and sustainability principles. Do you have questions or want to entrust us with the management of your used pallets? Write to us at dispo@ekologistyka24.pl.